mcmahon.intervw

Back to ArchiveThetford Town and its Covered Bridges. Thetford to Develop Over-height Warning System

Slated for Renovation

November 15, 2000

[Joe Nelson] You were telling me about some of the things you are doing with the Union

Village Bridge, including getting some of the timber from the bridge tested.

[Mark McMahon] Yes. That was one of the things we addressed when we initially received the

grant from the federal government and when we were talking to our contact with the state and

with the engineers. They wanted to remove some of the timbers as they proceed with the project

and actually test them for stress and other weight related [factors]. We were all in favor of doing

this because it's just one covered bridge out of a thousand covered bridges across the united states

-- if there is something that can be learned or better understood how covered bridges work and

can help the process of rehabilitating them so that towns don't just remove them and put up a

modern bridge. This has happened too often in recent history.

[JN] Replicas, you mean?

[JN] Replicas, you mean?[MM] No, not only replicas, but just completely get rid of a covered bridge because I think you'd find historically, certainly in the 50s and 60s, a lot of these covered bridges were taken down and a regular open span bridge was erected in its place. Certainly functionally and maintenance-wise [replacement] probably was easier and more cost effective for these small towns which have to bear the financial burden of maintaining these bridges. But one of the things we feel in preserving this bridge and also our Tucker Hill Bridge is that hopefully some of the testing and learning is going to help other towns to understand these bridges and help them preserve their bridges as well.

[JN] Who is the Town working with on the project?

[MM] Our project manager is Bert Moffatt of VTrans, and Hoyle, Tanner and Associates of Manchester N.H. One of the things we were looking for was to make sure the bridge was rated for 25 tons. Because we wanted to at least move our fire vehicle through it. The people on the other side of the bridge have been kind of lame ducks because for years, to get to them, it would require our fire department to come all the way around from across the tucker hill bridge. The town of Norwich would help out but it's still a long distance to travel. Originally when the engineers were doing their design work they came up with a 20 ton limit but we discussed it a little more and what they are going to be doing is try to work so that it would be able to handle a 25 ton, for instance, a fire truck, we're not talking an every day, ten trucks a day, but on occasion for a fire truck to go across.

[JN] The fire truck doesn't weigh 25 tons, right? That includes the safety factor?

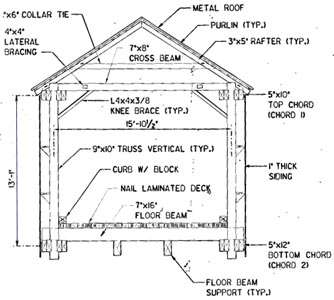

[MM] That is correct. One of the things the engineers proposed was steel beams underneath and we disagreed with that, and it required them to do research and come up with laminate.

[JN] So Glu-lam will be used under there?

[MM] Right.

[JN] So it's going to maintain the appearance of the bridge.

[MM] Absolutely. We asked that the steel guard rails on both bridge approaches be removed and a type of wood guard rail be in place. It would maintain the same safety standard, especially since we have the continuous concrete abutment that comes up about a foot to a foot and a half, so it wouldn't compromise the safety of oncoming traffic, but it would create a more historically appealing sight as you come towards the bridge.

[JN] It's pretty appealing now.

[MM] It's pretty appealing, but if you step back and really look at it, and one of the things we talked about is when you see all this beautiful wood and you see all these big steel guard beams, one of the things we asked is, was there a way to design something where we could maintain the steel guard rails but actually encompass them in stonework. The committee didn't think it had enough money to do something like that, so we asked if they would consider doing the wood and maybe the town down the road would consider doing some encompassing stone work just to make it a little more aesthetically pleasing.

The engineering study is pretty specific, they've been very accommodating, in fact they've been so accommodating that the federal government and the state agreed to forgo our 10 percent [matching money], so this whole project is costing the Town of Thetford about $1300.

[JN] And you get a new bridge.

[MM] No, hopefully it's not a new bridge. They've been very good and one of the things that we agreed to, and one of the conditions to go ahead with this grant was that we wanted to have the final say. If they came up with a design that we didn't think was appropriate, then we were willing to reject it, and even if it cost the town in the long run, we would have done it our selves. Fortunately that wasn't the case. The engineering plan that they came up with, we think fits in with what the town of Thetford wants, and we're willing to go ahead with it.

[JN] And the price is right.

[MM] The price is definitely right. It's going to make a lot of people happy and its going to free up some money that we can use on some other historical projects in town that we hadn't had a chance to get to because we were trying to cut corners and penny pinch to keep our taxes down. Construction starts in the spring of 2001.

[JN] Thank you, Mr. McMahon.

Mark McMahon can be reached through the Thetford Town Office email: thetford.clerk@valley.net - Attention Mark McMahon

return to top

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267, jcnelson@together.net

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267, jcnelson@together.net

No part of this web site may be reproduced without the written permission of Joseph C.

Nelson

Text Copyright © 2000, Joseph C. Nelson

This file posted December 28, 2000, rev. March 31, 2001